Water Pollution Control Plant

Author: Tony Park, P.E.

Preliminary Design: 2020

Millbrae established a pretreatment program to minimize the impact and hazards of wastewater discharged from residential, commercial, industrial, and mobile users. The wastewater discharged from these sources undergoes primary and secondary treatments at WPCP.

For several years, the WPCP operated a gas turbine-based cogeneration system that could produce up to 270 kW of electrical power. To produce more digester gas in the anaerobic digesters, the city operated a Fats, Oil, and Grease (FOG) receiving station.

A few years ago, the FOG receiving station was shut down because of operational issues caused by a changed composition of the received waste. The gas turbine cogeneration system included a digester gas treatment system intended to remove hydrogen sulfide and siloxane compounds. The gas treatment system consisted of hydrogen sulfide adsorption beds followed by a refrigeration system. Unfortunately, the refrigeration system did not work as initially designed, and siloxanes passed into the gas turbine combustion chamber. Combustion of siloxanes formed sand deposits on the turbine blades causing the system to fail.

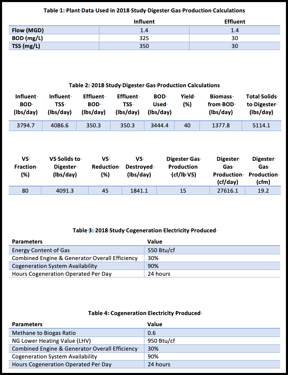

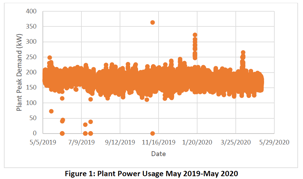

In 2018, a study was conducted on the digester gas production and plant power consumption data at the WPCP. The study recommended the replacement of the existing cogeneration system with a new cogeneration system to be able to use all the available digester gas supplemented with natural gas (NG) and to produce electricity close to the average plant demand. The study also evaluated various procurement options and recommended that the best and most cost-effective option is for the city is to own and operate this system.

The objective of this project was to formalize the basis of design to replace the existing Cogeneration System with a new 150 kW system as recommended in the 2018 study using current data. Replacement of the existing Cogen system that primarily relied on the FOG system with a smaller Cogen system without the FOG system posed some very unique challenges.

The first step for sizing the new cogeneration system was to estimate the amount of DG produced by the anaerobic digesters. This posed an interesting challenge because the WPCP did not have flowmeters installed to monitor the DG flowrate as most plants do.

Since the conventional analytical approach for estimating DG production was infeasible, a more empirical methodology was employed. DG production was calculated utilizing wastewater characteristic data. This provided a solid basis for determining the electrical output generated by beneficially using the available DG and sizing the new cogeneration system.

The available digester gas could only produce electricity less than half of the average plant demand. But the city expressed that they would like the new cogeneration system to be sized to meet the average plant electrical demand and also accommodate the electrical load of the future recycled water facilities.

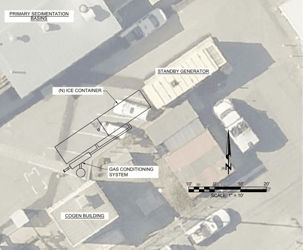

This required the new cogeneration system to operate over a very wide range with and without supplemental natural gas. The Internal Combustion Engine (ICE) engines have limited turndown capabilities. Two (2) ICE engines were selected to cover the entire desired operating range, which also provided redundancy for nearly continuous digester gas utilization (avoid flaring during engine shutdown for periodic maintenance).

The recommended dual ICE generator sets, and the associated gas conditioning system was too big to fit in the existing Cogen system location.

There is limited space available at the plant which is located on a tiny piece of land right next to the 101 freeway and the San Francisco International Airport and much of the available space is reserved for future tertiary system upgrades.

The one location available was too small to accommodate the two ICE engines in a separate enclosure. To minimize the footprint of the system so it would fit in the available footprint, an atypical single enclosure configuration housing both ICE was configured in collaboration with the manufacturers.

It’s a team effort from all sides.

LEE + RO was able to determine a solution and prepare the preliminary design of a new cogeneration facility that aligned with the city’s wide operating range requirements. The solution overcame the hurdle of a confined site, while also determined the appropriate Cogeneration technology, the number of engines, and gas conditioning technology.

This project established a clear path for the next phase which involves preparing detailed design documents for the construction of a new cogeneration facility so the city can once again start making beneficial use of the digester gas and reinforce its commitment to resource recovery.