Developing a chemical dosing control strategy based on chlorine residual

Year: 2021-2023

Author: Kevin Saleh

.jpeg?width=832&height=492&name=Hero%20(1).jpeg)

The District has experienced degraded water quality at TR Z3 Res due to nitrification caused by the loss of chlorine residual, excess free ammonia, and low water supply turnover within the existing reservoirs. To reduce nitrification in the system, chlorine and ammonia are dosed at the Turtle Rock Zone 1 to 3 Pump Station, but this process is susceptible to chemical precipitation within the pipe where the chemical is injected, necessitating multiple replacements of the injection pipe.

Nitrification:

Nitrification is a two-step process that first converts ammonia to nitrite and then converts nitrite to nitrate. Nitrification can occur in drinking water systems when naturally occurring ammonia is present, or when ammonia is added as part of a chloramine disinfection treatment process. Nitrification is caused by bacteria that derive energy from this conversion. These bacteria are generally classified as either ammonia-oxidizing bacteria (AOB) or nitrite-oxidizing bacteria (NOB). Nitrification usually occurs when water temperatures are above 15°C (59°F), although some case studies report nitrification occurring when temperatures were below 10°C (50°F).

Several operational conditions that promote nitrification include:

LEE + RO was contracted to design a reliable and efficient way for the District to store and distribute large volumes of potable water. To address the nitrification issues, this project will construct a chloramine booster station at TR Z3 Res. The District will retrofit the reservoir with a Chloramine Boosting System (CBS), which includes in-reservoir mixing, chemical storage/injection/dispersion equipment, and residual chlorine analyzers.

In potable water supply reservoirs, thorough mixing is required to ensure even distribution of the disinfectant and avoid pockets of older water that accelerate the decay of the disinfectant. Disinfectant decay creates an unfavorable situation where bacterial and algae growth is promoted. Such conditions cause an increase in pathogenic bacteria, microbial nitrification, and taste and odor problems. The formation of pockets of older water resulting from inefficient mixing within reservoir can also cause an increase in the pH of the water.

The American Water Works Association (AWWA) has noted that nearly two-thirds or more of the reservoirs with chloraminated water experience unwanted nitrification and a loss of residual disinfectant, especially when water temperatures rise during warm weather. When the temperature of chloraminated water rises above 60°F, rapid AOB growth (which is 13 times more resistant to chlorine than most bacteria) can occur, particularly on the floor and walls of the reservoir.

To avoid this nitrification scenario, the mixer must circulate the water completely, including along the walls and bottom of the reservoir, to maximize AOB exposure to available disinfectants.

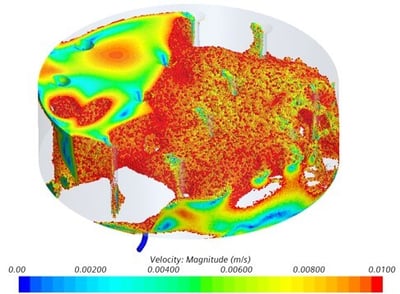

In the Turtle Rock Chloramine Booster Station Project, Computational Fluid Dynamics (CFD) was used to model multiple commercial mixer designs within the Zone 3 Reservoir’s inner and outer tanks. Mixer effectiveness was assessed based on the percentage of the reservoir volume that was a “low flow” zone.

CFD allowed for direct comparison of each mixer’s performance within the unique geometry of the Zone 3’s annular outer tank. Common mixer designs that perform admirably in other tanks did not perform well in this short annular tank. Without the use of CFD, it is likely that prior experience alone would have resulted in a suboptimal mixer design. The final optimized design resulted in a mixer selection, location, and orientation angle that efficiently minimized the dead zones within the Zone 3 Reservoir.

Proper access for installation and maintenance of mixers is crucial for maintaining high water quality in a reservoir. Without a proper access, repairs or replacements of mixers can be difficult and time-consuming, and may require divers or shutting down the reservoir, leading to service interruptions and reduced efficiency.

Construction of 3 new hatches was deemed necessary for this project. The new hatches will provide maintenance personnel adequate space for access to the mixers without the need to shut down the reservoir or employ the services of a diver. This advantage will reduce maintenance costs and keep water quality consistently high.

The project objective was to design and install a chloramine booster station at TR Z3 Res to address and preclude the nitrification and in-pipe chemical precipitation issues. To reach the goal, CFD modeling was utilized to optimize the mixing process, leading to more efficient use of energy and other resources. The modeling provided:

Additionally, during the design, potential maintenance issues were identified, that will ultimately lead to reduced O&M costs.