Projects: Wastewater Treatment Plants

Design: 2000 - 2020

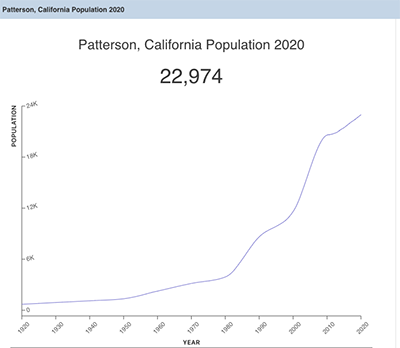

By the mid-1990s, Patterson recognized that its accelerating population growth required a Capital Improvement Program (CIP) to support its existing system rehabilitation and upgrades to meet the growing demands with limited funds. What complicated Patterson’s efforts, and challenged LEE + RO, was the two-decades evolution of requirements and limits enacted to protect groundwater quality implemented by the Central Valley Regional Water Quality Control Board (RWQCB).

In 1999, LEE + RO, in partnership with Swanson International, won its first contract to handle the Phase 1 Improvements to the city’s Water Quality Control Facility (WQCF). It was that opportunity that opened the door to a 20 plus-year relationship with the city of Patterson, a relationship that was developed over time through mutual learning, establishing trust, and ultimately serving one common purpose: design and implement innovative water and wastewater infrastructure solutions that deliver high-quality drinking water and reliable wastewater systems while protecting their environment.

.jpg?width=400&name=2000%20-%20Phase%20I%20Treatment%20Plant%20Expansion%20(AIPS).jpg)

The successful completion of Phase 1 Improvements led to the designing of the Phase 2 Improvements, which added a second set of Advanced Integrated Pond System (AIPS) process ponds to increase the Water Quality Control Facility (WQCF) capacity to 2.25 mgd.

Midway through the AIPS design phase, the RWQCB concluded that pond systems, like the AIPS, would no longer be able to produce effluent with levels of nitrogen low enough to protect groundwater from the accumulation of harmful salts, which had evolved as a significant regional concern in the Central Valley.

%201.jpg?width=400&name=2005%20-%20Phase%20II%20Treatment%20Plant%20Expansion%20(SASTS)%201.jpg)

LEE + RO began developing alternatives that would not only meet RWQCB’s new nitrogen limits, but also deliver value to the city. LEE + RO selected an activated sludge oxidation ditch with anoxic zone as this treatment process would be able to meet the limits while providing a high level of reliability and ease of operation for city staff. Additional facilities included a new circular secondary clarifier, aerobic digesters, sludge drying beds, percolation/evaporation ponds, and improved power distribution and emergency standby power.

LEE + RO completely reimagined and redesigned the project in less than six months so that the city could keep up with its rapid growth and RWQCB’s regulatory requirements. The project resulted in excellent effluent quality and nitrogen removal, and the process is still in operation today.

In 2007, the RWQCB instituted new discharge limits on the city’s treatment plant. Total nitrogen, which had no previous limit, was set to 8 mg/L. At the time, typical performance of the AIPS was 50 mg/L and the North Activated Sludge System was 35 mg/L. The RWQCB’s changes meant that the older activated sludge system that the city was operating could no longer operate in compliance.

Midway through design, LEE + RO was tasked with determining the best approach to meet these new limits while minimizing the city’s capital outlay.

LEE + RO determined that the most appropriate and cost-effective approach was to convert the current activated sludge system to a Simultaneous Nitrification/Denitrification (SNdN) process. By carefully controlling oxygen transfer within the existing oxidation ditch, the SNdN process could do with one tank what other systems accomplish using multiple tanks. This innovative process modification delivered huge value to the city. With the SNdN modification coming in at 15% of the cost of a new Oxidation Ditch, this design saved the city more than $6 million in capital costs.

In 2010, the city’s WQCF needed improvements to the solids handling facilities. In locations like Patterson, where land is plentiful, sludge drying beds offer a low-cost, low-maintenance solution for treatment plants that need to dewater their wastewater solids. However, factors like the weather (especially during the cold/wet winter months) and the city’s growing size increased solids production, and the city found that solar-based dewatering was no longer sustainable.

LEE + RO was asked to develop and analyze numerous alternatives for mechanical dewatering, including high-speed centrifuges, belt filter presses, and screw presses.

To meet aggressive regulatory deadlines set by RWQCB, successful project delivery would require a fast-track approach. After quickly analyzing alternatives during preliminary design, the city selected a high-speed centrifuge for dewatering. To accelerate the project schedule LEE + RO recommended a skid-mounted design that greatly accelerated both design and construction because the time-consuming work of coordinating numerous pieces of equipment to operate in concert was handled by the equipment vendor. LEE + RO developed a final design for the centrifuge facility in five weeks and construction was completed in 12 months. Patterson and LEE + RO went from project conceptualization, preliminary and final design, and construction/startup in less than 30 months.

%20Hydraulic%20improvements.jpg?width=300&name=2015%20-%20South%20Activated%20Sludge%20System%20(SASTS)%20Hydraulic%20improvements.jpg)

In 2015, the city retained LEE + RO for emergency assistance to develop solutions that could be quickly implemented to fix a hydraulic bottleneck at the WQCF, which significantly reduced the peak wet weather capacity of the treatment plant.

The concern was that heavy “El Niño” rains would result in significant inflow/infiltration resulting in a spill at the treatment plant or flooding throughout the collection system. To complicate matters further, the construction constraints were just as daunting: re-configuring the piping inside of the existing process facilities would be difficult since the subsequent downstream process was a 1,000,000-gallon process tank, with no means of isolation. This would require either emptying the existing process tank, a lengthy, complicated, and costly affair that would require the restart of the biological process; or developing an alternate method to provide hydraulic isolation of this tank.

LEE + RO elected to keep the 20-foot deep tank online and used construction divers to install a temporary isolation plug. Divers inserted a 2-foot diameter plug into the tank inlet which lay submerged under 10 feet of wastewater. The inserted plug provided temporary hydraulic isolation which enabled the replacement of the upstream bottleneck. This creative solution avoided a biological restart of the 1,000,000-gallon tank with the following resulting outcomes for the city:

%20Anoxic%20Zone%20Upgrade%20and%20Clarifier%20Replacement.jpg?width=400&name=2020%20-%20North%20Activated%20Sludge%20System%20(NASTS)%20Anoxic%20Zone%20Upgrade%20and%20Clarifier%20Replacement.jpg)

In 2018, LEE + RO was tasked with designing the second phase of upgrades to the City’s original oxidation ditch to increase treatment capacity and improve nitrogen removal.

Expand on the solution devised in 2005 to meet WQCFs new requirements by relying on well-timed, modular additions to the treatment process.

LEE + RO designed a 100,000-gallon anoxic system that increased the system’s ability to remove nitrogen and make both of Patterson’s existing oxidation ditches operate similarly. The upgrade also included mechanical replacement of the system’s two 40-foot diameter circular clarifiers and reconfiguration of the piping at the distribution structure, activated sludge pump station and effluent pump station, which performs better than the SASTS built in 2005. The result: nitrogen removal by 50% and the process improvements extended the service life of WQCF’s secondary treatment process for another 15 years.

It’s a team effort from all sides.

Whether completely redesigning processes to meet new regulations or repurposing existing infrastructure, it can only be accomplished through a team effort built on collaboration and communication.

Our job was simple. Being agile enough to deal with the myriad of changes resulting from explosive growth and a dynamic regulatory environment isn’t easy, but it’s exactly the kind of engineering design support a city like Patterson needs. And it’s what LEE + RO always proudly delivers: responsive service, innovative approaches to design, technical competence, and the courage to give honest answers in service of any project.