Sewer Pump Station Replacement

Year: 2021

Author: Boyana Angelova, P.E.

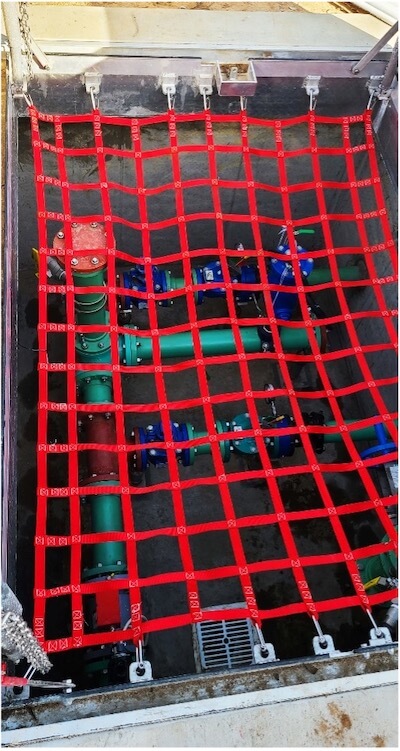

The City partnered with Nasland Engineering (Prime Consultant) and LEE + RO (Engineer of Record) on designing an improved cost-effective pump station facility with enhanced work safety and operability for O&M personnel. The new improvements included a wet well conversion to a submersible pit, new submersible pumps, new mechanical discharge piping vault with new isolation valves, check valves, flow meter, complete relining of the wet well, discharge and suction manholes, a new water source with hose bib connection, new exterior lighting, and new electrical and instrumentation and controls (I&C) system.

The pump station is located in the picturesque community of Coronado Cays where a large percentage of homes border the San Diego Bay. The 1973-constructed, below grade facility services a large percentage of single-family homes in the community. The City determined that the pumping equipment in the original facility was nearing the end of its useful life. Moreover, based on current safety standards, there were concerns about the safe access of personnel into this underground facility and issues with sanitary sewer overflows. The original pump station dry well with suction lift pumps was configured in a small underground space about 7-ft. in diameter. A 3-ft. diameter vertical shaft and 16 ft ladder were the sole access to this dry well. This made the operation, maintenance, and removal of pumps and other appurtenant equipment from the dry well very challenging, with significant safety code concerns.

The planning and design scope for this project included upgrading the facility for improved personnel safety, reliability, pumping capacity, and energy efficiency. In preparing the Conceptual Design Report, it was recommended to construct a new pump station with submersible pumps that can be removed through an at grade access hatch, an underground discharge valve vault, and new power, control and telemetry panels located at grade. The new pump station design pumping capacity is 225 gpm.

Several challenges were overcome during the design and construction of the pump station upgrade. With the close proximity of San Diego Bay to the construction site, groundwater level was a significant concern during construction. Therefore, dewatering was a significant construction work item. The groundwater had to be collected in a series of slotted pipes at various points around the excavation. Then the groundwater was pumped into a sediment separating tank before disposal in the sewer system.

A key planning and design criteria by the City of Coronado was that the construction should avoid any negative impacts on the adjacent community. Additionally, to accomplish the improvements, a two-phase temporary sewer bypass pumping plan with pump redundancies had to be developed during design for uninterrupted operation.

In the design of many municipal sewer pump stations, there is generally no consideration given to architectural treatment and they are typically hidden inside a fenced property away from adjacent development. The City’s Trinidad Pump Station main mechanical equipment is situated below grade in an open space park area immediately adjacent to a San Diego Bay side residential neighborhood. Careful attention was given during design to avoid any impacts to the adjacent community from pump noise levels, particularly during nighttime hours, odor emissions, and maintenance vehicle access. The pump station site was extensively landscaped with a balanced blend of ornamental plants and a lawn area that provides an aesthetically pleasing open space area.

Pump equipment maintenance and safety is a significant concern for the City. Since the improvements, the pump equipment can be much more readily maintained and removed for major servicing. City staff also realized a significant project cost savings with the new configuration utilizing submersible pumps in a renovated wet well, and discharge valves installed in an easily accessible compact discharge valve vault. The floor of the valve vault was designed above the groundwater level thereby avoiding potential water intrusion related issues. The new valve vault also incorporates a dedicated emergency suction lift pump connection should it ever be required during emergency conditions. For emergency power redundancy, an emergency generator receptacle connector and transfer switch were also incorporated.

In order to reduce overall project cost and community impacts, such as the shallow groundwater level, the lower part of the original wet well was retained and modified. The modification included a new 9 ft wet well extension constructed to finish grade. With the close proximity of the Bay to the construction site, dewatering was a significant construction work item. The innovative design solution of modifying the existing wet well and converting it into a submersible pit provided savings on cost and improved the schedule. The existing wet well was lined with a PVC liner, which was heavily delaminated. The existing liner was completely removed and the entire wet well structure was coated with a 100% solids polyurethane Zebron coating. In addition, a two-phase sewer bypass pumping plan was developed so that construction began with an aggressive spill prevention plan. Given the critical requirement to avoid any sewer overflows to the Bay during construction, this bypass pumping operation incorporated redundant pumping equipment and continuous monitoring via telemetry instrumentation.

The City’s Trinidad Pump Station Replacement project improves O&M personnel access and maintenance safety, provides improved facility operability, reduced energy consumption, reduced O&M and life cycle costs, and creates an appealing landscaped open space area with an underground facility located adjacent to the San Diego Bay shoreline.

All phases of this project from preliminary planning through construction completion were accomplished with outstanding collaboration and teamwork by all project stakeholders. The new more efficient submersible pumps will operate with significant energy savings, and lower life cycle costs. The upgraded pumping facility provides a very cost-effective facility with enhanced work safety and operability for O&M personnel, reduced sanitary sewer overflow, improved energy efficiency, and lower O&M and facility life cycle costs.