Wastewater/Recycled Water Pump Station

Design: April 2014 – December 2016

Construction: January 2017 – September 2019

Cost: $13.5 MM

This project will save millions of gallons of potable water each year, protects our coastal aquifers from seawater intrusion, provides an economical alternative to using potable water for industrial processes, and reduces the amount of (treated) sewage we release into the ocean—all while making beneficial reuse of an underappreciated, untapped resource: Los Angeles’ raw wastewater.

West Basin can provide this bounty of recycled water by taking treated secondary effluent from the nearby Hyperion Water Reclamation Plant (HTP) and treating it with state-of-the-art micro-filtration, reverse osmosis, and UV disinfection processes. In doing so, WBMWD essentially takes plain municipal wastewater and makes it cleaner than the water we drink at home! And they plan to make even more if they could find a way to reliably deliver even more of HTP’s secondary effluent.

As with any recycled water purveyor, maintaining capacity is critical for WBMWD, as their contractual obligations require that they deliver recycled water at all times—and if WBMWD doesn’t have enough, they are obligated to furnish precious and expensive potable water in its stead. This obligation represents a substantial financial risk for the District and in general, requires maximum reliability for all WBMWD’s recycled water facilities.

In addition, the existing pump station was fed by a single power source without provisions for emergency power or a redundant power feed. Construction would require tapping into wetted, pressurized facilities and messy underground construction on a busy arterial road. Complex treatment processes at HTP, the largest wastewater treatment plant in the Western United States, and ECL would need to be protected at all times during construction, and the sheer number of stakeholders made communication and coordination challenges.

Now, imagine designing a facility meant to meet these challenges and house three (3) large, 800 hp, 4,160V pumps within a 24’ L x 18’ W project site—a footprint just larger than two parking spots. Just for good measure, add the complexity of a deep excavation constrained by tidally influenced groundwater.

To overcome this challenge, LEE + RO developed a custom shoring solution that incorporated Giken Silent Pile Technology, ground improvement (grout injection), a sealed cofferdam, and a conventional tremie slab to seal off the excavation and make construction possible. It’s a tight fit, L+R developed a pump station layout that has space for three pumps, associated valves, and large diameter suction and discharge pipe headers.

Power Reliability:

The existing HSEPS was powered by a single 34.5 kV feeder from LADWP, without a redundant feed or onsite emergency power. L+R conducted an alternative analysis and determined that the installation a 3,000 kW diesel-powered generator with an automatic transfer switch provided better value and increased reliability to the District than adding a redundant LADPW feed. In addition to emergency power, L+R also designed modern power distribution, motor control infrastructure, and proprietary, software-driven pump control to increase efficiency, reliability and pump service life.

Wet Taps:

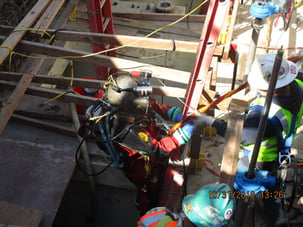

Prior to construction, many wondered how we would approach the technical challenge of tying in HSEPS’ suction piping because it required a high-stakes connection to the existing HTP secondary effluent channel, a 60” pressure pipeline. Any mistakes during tie-in would result in a catastrophic spill of secondary effluent and result in major damage to the facility. As such, L+R’s approach to this work was an abundance of caution and attention to detail and centered around the use of highly qualified construction divers and welders, inserted into the pipe at low flow to make the necessary cuts and welds for the connection of the pumps’ new suction piping. A combination of high-level coordination, detailed construction drawings and specifications meant that this high-risk portion of the work went smoothly, without drama.